Unleashing the Full Potential of LED Assembly: Uncovering the Key Factors for Optimal Results

LED (Light Emitting Diode) technology has revolutionized the lighting industry, offering greater energy efficiency, longer lifespan, and improved environmental sustainability compared to traditional lighting solutions. As the demand for LED lighting continues to grow, it becomes crucial to understand the key factors that contribute to the optimal performance of LED assembly. This article aims to uncover these factors and highlight their significance in unleashing the full potential of LED assembly.

1. Thermal Management:

LEDs are highly sensitive to temperature variations, and excessive heat can drastically reduce their performance, efficiency, and lifespan. Efficient thermal management is, therefore, a critical factor in achieving optimal LED assembly results. This can be achieved through proper heat sinking, which involves designing and implementing effective heat dissipation mechanisms, such as heat sinks, thermal pads, and fans. Additionally, adequate ventilation and ambient temperature control should be considered to ensure optimal thermal conditions for LED operation.

2. Optimal Current-Driving:

Proper current-driving is essential for maximizing the performance and longevity of LEDs. Overdriving LEDs can result in accelerated aging, reduced efficiency, and light output degradation. Underdriving, on the other hand, can lead to diminished brightness and inadequate light output. To achieve the optimal current-driving level, sophisticated LED drivers and controllers should be utilized, taking into account the specific requirements of the LED assembly and the desired level of performance.

3. Quality of Components:

The quality of components used in LED assembly greatly influences the overall performance and reliability of the lighting system. Low-quality LEDs can have significant variations in color temperature, intensity, and lifespan, leading to inconsistent lighting output and premature failures. It is crucial to use reputable suppliers and select components that are tested and certified to ensure their compatibility and reliability.

4. Optics and Lens Design:

Optical elements, such as lenses, reflectors, and diffusers, play a critical role in maximizing the light output and efficiency of LED assemblies. Proper optics and lens design can control the directionality of light, minimize light loss, and improve the uniformity of illumination. Optical simulations and design optimization techniques should be employed to determine the most suitable optics for the specific application, taking into account factors such as beam angle, light distribution, and color rendering requirements.

5. Robust Manufacturing Processes:

The manufacturing processes employed in LED assembly significantly impact the quality and reliability of the final product. Strict quality control measures should be implemented throughout the manufacturing chain to ensure consistent and reliable performance. From the selection of raw materials to the assembly and testing processes, each step should adhere to industry standards and best practices. Implementing advanced manufacturing techniques, such as surface mount technology (SMT), can improve accuracy, yield, and efficiency in LED assembly.

In conclusion, to unleash the full potential of LED assembly, it is crucial to consider the key factors discussed above. By focusing on efficient thermal management, optimal current-driving, high-quality components, appropriate optics and lens design, and robust manufacturing processes, the performance, lifespan, and reliability of LED lighting systems can be maximized. With the continued advancements in LED technology, understanding and implementing these factors become even more crucial in achieving the desired lighting outcomes and driving the adoption of LED lighting solutions across various industries.

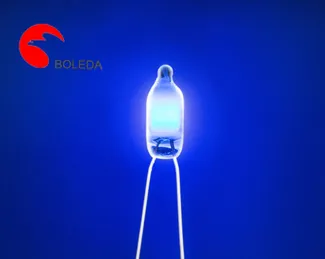

NE-2 orange color

NE-2 orange color 410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes

410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes 513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal

513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps

E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen

Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen 6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable

6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable 10 mm Neon indicator lamps, signal lights with PVC cable

10 mm Neon indicator lamps, signal lights with PVC cable 12 mm Neon indicator lamps red color with Crimped resistor PVC cable

12 mm Neon indicator lamps red color with Crimped resistor PVC cable 3mm5mm Led light, LED lamp with resistor and diode

3mm5mm Led light, LED lamp with resistor and diode 3 mm leds roundStrawflat shape, water cleardifussed

3 mm leds roundStrawflat shape, water cleardifussed 5 mm leds roundStraflat shape, water cleardifussed

5 mm leds roundStraflat shape, water cleardifussed

Comment

(0)