Boosting Led assembly performance: Unraveling the Science Behind Success

Introduction:

The LED (light-emitting diode) industry has experienced significant growth in recent years due to its energy-saving properties and long lifespan. However, as the demand for LED lights continues to increase, so does the need for manufacturers to improve the performance and efficiency of Led Assembly processes. This essay will delve into the science behind achieving success in LED assembly, exploring various factors that can boost performance and enhance overall product quality.

The Science behind Success:

1. Optimal Thermal Management: LED lights generate heat during operation, which can significantly impact their performance and longevity if not properly managed. Effective thermal management involves minimizing heat generation, conducting it away from the LED chip, and dissipation into the surrounding environment. Maintaining low operating temperatures in LED assemblies not only enhances performance but also prolongs the lifespan of the product.

2. Accurate Soldering Techniques: Soldering is a crucial step in LED assembly that ensures proper electrical connections between LED chips and the assembly substrate. Achieving high soldering quality involves precise control of temperature, solder alloy composition, and flux application. Additionally, selecting the appropriate soldering method based on the assembly's complexity and design is essential. Optimized soldering techniques result in reliable electrical connections, preventing potential failures and improving overall product performance.

3. Advanced Optical Analysis: The performance of an LED light is determined by its optical properties, including luminous efficiency, color rendering index (CRI), and color temperature. Manufacturers can enhance LED performance by utilizing advanced optical analysis tools to assess these parameters accurately. By monitoring and adjusting the optical properties during the assembly process, manufacturers can achieve higher light output, better color accuracy, and improved overall quality of light.

4. Thorough Quality Control: Implementing robust quality control measures ensures consistent performance and reliability of LED products. Quality control involves conducting rigorous testing at various stages of the assembly process, including pre-assembly verification of components, inspection during and after soldering, and final quality checks. By continuously monitoring and improving quality control procedures, manufacturers can minimize defects and ensure that every LED assembly meets the required standards for performance and reliability.

5. Efficient Manufacturing Processes: Enhancing LED assembly performance involves streamlining manufacturing processes to reduce production time and costs. Advanced automation technologies and machinery can be employed for precise positioning of LED chips, accurate dispensing of solder paste or adhesive, and efficient inspection and testing. With efficient manufacturing processes in place, manufacturers can increase the output, reduce resource wastage, and improve overall productivity.

Conclusion:

The science behind achieving success in LED assembly is multi-faceted, encompassing various factors such as thermal management, soldering techniques, optical analysis, quality control, and manufacturing efficiency. By focusing on these aspects and continually improving processes, manufacturers can boost performance and enhance the overall quality and reliability of LED lights. As the LED industry continues to evolve, unraveling the science behind LED assembly success becomes critical for ensuring sustainable growth and meeting the increasing demand for energy-efficient lighting solutions.

NE-2 orange color

NE-2 orange color 410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes

410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes 513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal

513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps

E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen

Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen 6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable

6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable 10 mm Neon indicator lamps, signal lights with PVC cable

10 mm Neon indicator lamps, signal lights with PVC cable 12 mm Neon indicator lamps red color with Crimped resistor PVC cable

12 mm Neon indicator lamps red color with Crimped resistor PVC cable 3mm5mm Led light, LED lamp with resistor and diode

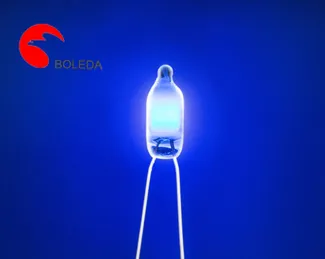

3mm5mm Led light, LED lamp with resistor and diode 3 mm leds roundStrawflat shape, water cleardifussed

3 mm leds roundStrawflat shape, water cleardifussed 5 mm leds roundStraflat shape, water cleardifussed

5 mm leds roundStraflat shape, water cleardifussed

Comment

(0)