Unveiling the Secrets to Flawless Neon lamp Assembly

Introduction:

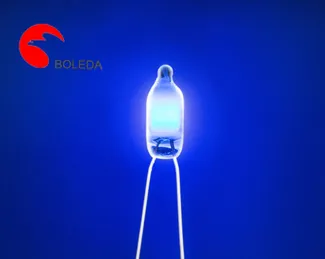

Neon lamps have become popular due to their vibrant and eye-catching colors. These lamps are widely used in various industries, including signage, advertising, lighting, and art installations. However, achieving a flawless Neon lamp Assembly requires attention to detail and adherence to specific techniques. In this article, we will unveil the secrets to flawless neon lamp assembly and provide insights into the process.

Choosing the Right Components:

The first step in achieving a flawless neon lamp assembly is selecting the right components. This includes choosing the appropriate neon tubes, electrodes, transformers, and housing materials. Neon tubes are available in various diameters and colors. It is essential to choose neon tubes that match the design requirements and ensure compatibility with the chosen transformer.

The electrodes play a crucial role in the assembly and performance of a neon lamp. The electrodes should be properly selected to provide stability and longevity to the lamp. Transformer selection is equally important, as it determines the electrical power supply to the neon tubes. Selecting a high-quality transformer ensures stable and reliable illumination.

Assembly Techniques:

Neon lamp assembly requires precision and attention to detail. The following techniques can help achieve a flawless assembly:

1. Tube Cleaning: Before starting the assembly, it is crucial to clean the neon tubes thoroughly. Any dirt or contaminants on the inside can affect the performance of the lamp. Specialized cleaning solutions should be used, and the tubes should be rinsed and dried properly before assembly.

2. Electrode Handling: The electrodes should be handled with care to prevent damage or breakage. They should always be aligned properly with the ends of the neon tubes. Ensuring a tight and secure connection between the electrodes and tube is essential for optimal performance.

3. Gas Filling: Neon lamps require a specific gas combination to produce the desired colors. The process of gas filling should be carried out in a controlled environment to prevent air or moisture from entering the tube. Maintenance of a vacuum pump and a regulated gas supply system is necessary for accurate and consistent gas filling.

4. Sealing Techniques: Proper sealing of the neon tubes is vital to protect them from external elements, such as moisture and dust. Various sealing techniques, including the use of silicone or epoxy, can be employed. The selection of the sealing material should match the application requirements and provide long-term durability.

Quality Control:

To ensure flawless neon lamp assembly, rigorous quality control measures should be implemented. This includes thorough testing of the assembled lamps for functionality, luminosity, color accuracy, and overall performance. In addition, checks should be conducted to ensure that the lamps meet safety standards and are resistant to environmental conditions such as heat, cold, and humidity.

Conclusion:

Flawless neon lamp assembly requires careful attention to detail and adherence to specific techniques. The selection of the right components, precise assembly techniques, and rigorous quality control measures all contribute to achieving impeccable neon lamps. By following these secrets, manufacturers, artisans, and enthusiasts can create neon lamps that capture attention, enhance aesthetics, and provide reliable illumination.

NE-2 orange color

NE-2 orange color 410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes

410 613 Neon lamp with resistor, cable and sleeve, resistor neon tubes 513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal

513 616 Neon lamp with resistor and cable and sleeve and ring terminal L terminal E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps

E10BA9S Plastic Shell Tin soldering, butt welded, crimped Neon Glow Lamps Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen

Fuse type Neon Lamp Tin soldering, butt welded, crimped with resistor for test pen 6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable

6 mm Neon indicator lamps, indicating lamps with resistor and PVC cableSilicone cable 10 mm Neon indicator lamps, signal lights with PVC cable

10 mm Neon indicator lamps, signal lights with PVC cable 12 mm Neon indicator lamps red color with Crimped resistor PVC cable

12 mm Neon indicator lamps red color with Crimped resistor PVC cable 3mm5mm Led light, LED lamp with resistor and diode

3mm5mm Led light, LED lamp with resistor and diode 3 mm leds roundStrawflat shape, water cleardifussed

3 mm leds roundStrawflat shape, water cleardifussed 5 mm leds roundStraflat shape, water cleardifussed

5 mm leds roundStraflat shape, water cleardifussed

Comment

(0)